What should be done when a senior manager of a concrete batching plant encounters a fault in a reversing valve? How to quickly find the cause of its failure? We all know that the maintenance work of managers will directly affect the progress of the entire project. Normally there are three types of fault phenomenon of the reversing valve of concrete batching plant:

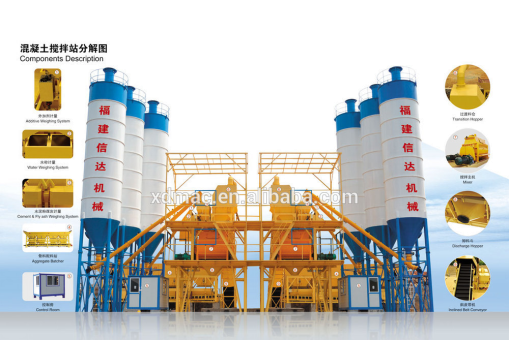

(Concrete Batching Plant Components Description by Fujian Xinda Machinery)

The valve cannot be reversed or the reversing action is slow, the gas leaks, and the solenoid pilot valve is faulty.

Correctly deal with the failure of the reversing valve in the concrete batching plant equipment:

(1)When encountering the reversing valve of the concrete mixing plant cannot be reversed or the reversing action is slow, which is usually caused by poor lubrication, stuck or damaged springs, oil or impurities stuck on the sliding part. In this regard, it is necessary to check whether the operation of the atomized lubricator is normal and whether the viscosity of the lubricant is appropriate. If necessary, replace the oil, clean the sliding part of the reversing valve, or replace the spring and reversing valve.

(2)After a long period of use, the reversing valve of concrete mixing plant is prone to wear of the valve sealing ring, damage to the valve stem and valve seat, resulting in leakage of gas in the valve, slow movement of the valve, or malfunction of the valve. At this point, the seal, stem, and valve seat should be replaced, or the reversing valve should be replaced.

(3)If the solenoid pilot valve inlet and outlet holes are blocked by fatlute or other sundries, closed lax, active iron core is stuck, the circuit has a fault, etc., can cause the reversing valve can not be properly reversed. For the first three cases, the fatlute and impurities on the pilot valve and active core should be cleaned. The circuit fault is generally divided into control circuit faults and electromagnetic coil faults.

Before checking the circuit fault, you should first turn the manual valve of the reversing valve a few times to see if the reversing valve works normally under the rated pressure. If the normal reversing is possible, the circuit is faulty. When the concrete mixing plant manager is inspecting, can measure the voltage of the electromagnetic coil with meter to see if the rated voltage is reached. If the voltage is too low, the power supply in the control circuit and the associated travel switch circuit should be further checked. If the reversing valve cannot be normally reversed at the rated voltage, check whether that the solenoid's connector (plug) is loose or the contact is unfirm. The method is to pull out the plug and measure the resistance of the coil (usually between a few hundred ohms and a few thousand ohms). If the resistance is too large or too small, it indicates that the electromagnetic coil is damaged and should be replaced.

Copyright © 2015-2024 Fujian Xinda Machinery Co., Ltd..All Rights Reserved.Powered by dyyseo.com