Products

- Ready Mixed Concrete Plant

Ready Mix Concrete Batching Plant

Concrete Batching Plant HZS120 Individual Weighing System Batch Mixer

XDM Low Pollution RMC Plant 60m3/h Small Concrete Batching Plant HZS60

Brand:

XDMItem NO.:

HZS120Payment:

T/T or L/CProduct Origin:

ChinaShipping Port:

Xiamen PortLead Time:

35days

Ready mixed concrete batching plant come with automatic twin-computer synchronization controlling systems that are capable of controlling and managing production flow with one or two computers. Our products widely apply for pre-cast concrete concrete pipes, dam construction and marine construction.

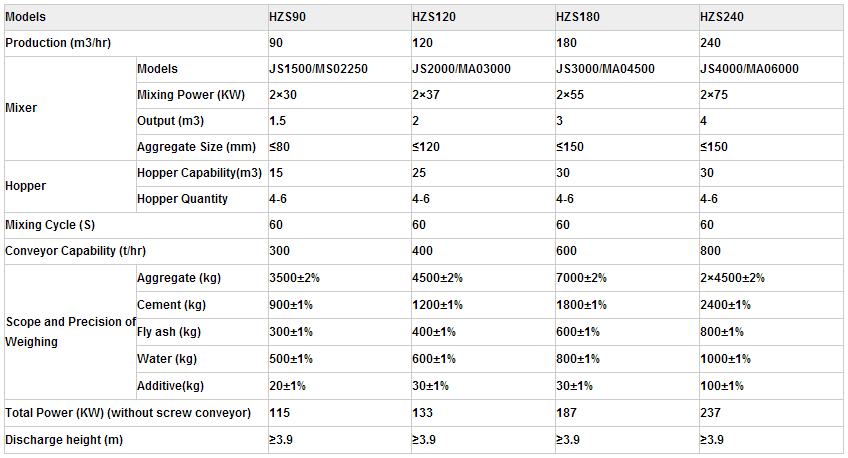

Specification of Ready Mixed Concrete Batching Plant

|

|

The aggregate batcher can be designed to installation underground, partially underground or on the ground. The aggregate hopper can accommodate 3-5 hoppers. The hopper discharge gate speeds are pneumatically controlled by the computer to discharge the aggregate into the weighing hopper. The weighing of the aggregate can be done in separate or accumulative models according to the operational form. |

|

|

The aggregate conveyor belt system is truss-framed for easy assembly. The inclination angle is normally less than 20 degrees; however, if the chevron (groovy) pattern belt is used, the inclination angle can be up to 20 to 45 degrees. The belt tension device is a standard weight-drop type for easy adjustment. The conveyor belt system is completely sealed. |

|

|

By using twin-shaft compulsory mixer, it mixes evenly and rapidly, achieving good mixing effect for all kinds of dry concrete, semi-dry concrete and plastic concrete. Multi-angle stirring arm avoids the phenomenon of concrete holding shaft. When the mixer main engine works the mixing shaft counter rotates. The materials remain in boiling motion under the action of the mixing blade. Meanwhile, under the shearing action of the stirring arm, the material is fully mixed in a relatively short period of time. |

|

|

Pump straight into weighing hopper or gravitationally feed into the weighing hopper through the upper storage tank. According to different circumstances, a three-point or single-point sensor suspension is adopted. The weighed admixture and water enter into the mixer according to the instructions. |

|

|

Powder is delivered to corresponding weighing hopper by screw conveyor or the pneumatic conveying. The number of weighing hoppers is decided as required, being generally one to three hoppers. After being weighed the powder is put into the mixer in accordance with the instruction. All powder sensors use three-point suspension. |

|

|

The control system uses domestic advanced double machine synchronized control and is equipped with specialized UPS power supply, high performance long-life Siemens PLC, high speed and high precision weighing unit module, the international famous low-voltage electrical component, and is combined with our professional control and monitoring software. In the concrete mixing equipment industry our company creatively adopts the high performance PLC+IPC (Industrial Personal Computer) control system which achieves the most reliable operation, the lowest failure rate, the easiest failure processing, and the lowest requirement for the capacity of the maintenance personnel. All these concur towards our company’s quality request – the best service is no maintenance. |

Main Technical Parameters of Ready Mixed Concrete Batching Plant

90m3/h Ready Mixed Concrete Batching Plant

90m3/h Ready Mixed Concrete Batching Plant

precast Ready Mixed Concrete mixing Plant is easy for supply big consturuction projects

120m3/h Ready Mixed Concrete Batching Plant

120m3/h Ready Mixed Concrete Batching Plant

Ready Mixed Concrete Mixing Plant is our professional products from China

150m3/h Ready Mixed Concrete Batching Plant

150m3/h Ready Mixed Concrete Batching Plant

150m3/h ready mix concrete batching plant, fully automatic control system, flat belt conveying system

60m3/h Ready Mixed Concrete Mixing Plant

60m3/h Ready Mixed Concrete Mixing Plant

High quality 60m3/h ready mix concrete mixing plant with good price

2x90m3/h Ready Mixed Concrete Batching Plant

2x90m3/h Ready Mixed Concrete Batching Plant

Ready Mixed Concrete Machine can produce ready mix concrete ,then delivery by truck to jobsite

2x120m3/h Ready Mixed Concrete Batching Plant

2x120m3/h Ready Mixed Concrete Batching Plant

ready mixed concrete batching is for concrete construction machine

2x180m3/h Ready Mixed Concrete Batching Plant

2x180m3/h Ready Mixed Concrete Batching Plant

our factory is produce Ready Mixed Concrete Mixing Plant.

180m3/h Ready Mixed Concrete Batching Plant

180m3/h Ready Mixed Concrete Batching Plant

we can supply high quality of ready mix concrete batching plant

Friendly Links :

Copyright © 2015-2026 Fujian Xinda Machinery Co., Ltd..All Rights Reserved.Powered by dyyseo.com