Products

- Continuous Mixing Plant

Cold Asphalt With Soil Mix Mixer Control by Computer

Concrete Batching Plant HZS120 Individual Weighing System Batch Mixer

XDM Low Pollution RMC Plant 60m3/h Small Concrete Batching Plant HZS60

Brand:

XDMPayment:

T/T, LC at sightMarket Price:

$109000Price:

$105000/setProduct Origin:

ChinaColor:

YellowShipping Port:

Xiamen PortLead Time:

30 working daysCold asphalt with soil mix mixer control by computer

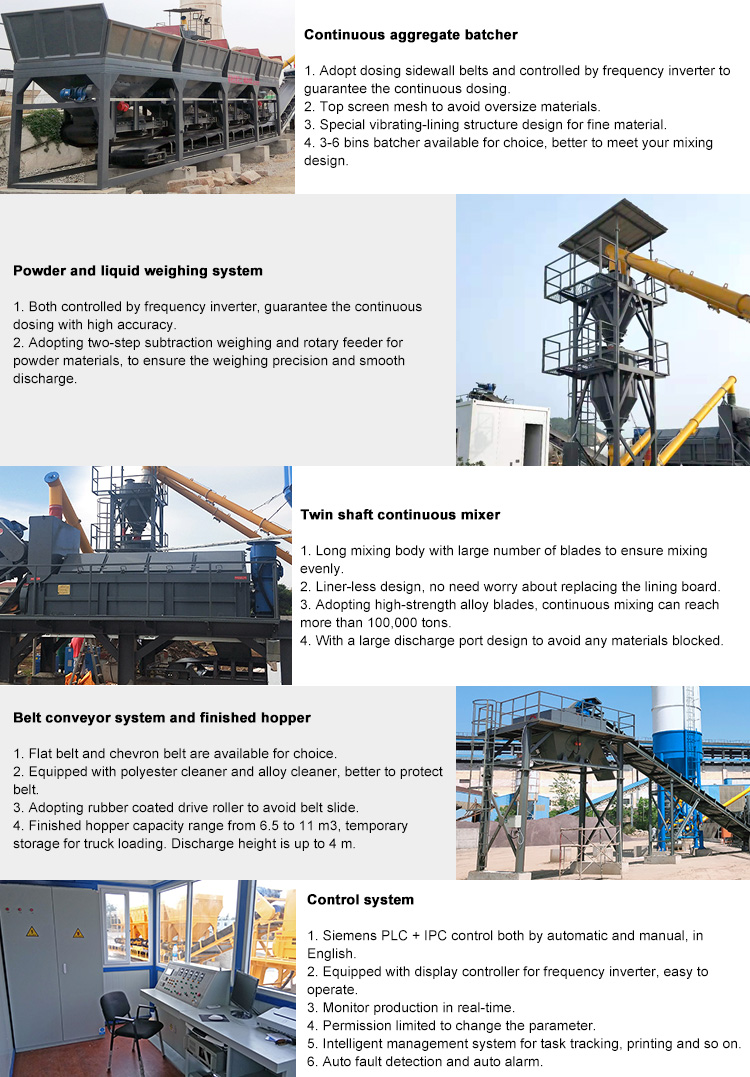

Cold asphalt with soil mix mixer control by computer are fully automatic by computer which provide fault diagnosis alarm on ready to ensure continuous production. We use famous brand for the electronic component ,like Siemens,LS and Schneider.PLC main controller is equipped with an industrial control computer and touch screen, easy to operate.

Cold asphalt with soil mix mixer control by computer

1. Production:300T/H - 500T/H

2. Aggregate hoppers: 4x10m3

3. Easy operation with fully automatic by PLC

4. Horizontal twin shaft continuous mixer

Cold asphalt with soil mix mixer control by computer is consists of Aggregate Batcher, Belt Conveyor, Silos, Screw Conveyor, Continuous Mixer,Finished Products Storage Hopper, Control Room and Pneumatic System.

1.Aggregate hopper:

Cold asphalt with soil mix mixer control by computer with aggregate hoppers of 3, 4, 5 or 6(as per projects required). Each aggregate hopper capacity is 10-12m3.Modular structured aggregate storage bin, flexible for different mixing design. The aggregate weighing system is by load cell with frequency transformer working together.

2.Belt conveyor:

Cold asphalt with soil mix mixer control by computer use thickness of 10mm flat belt to convey aggregate into mixer, after finished mixing, use belt again to convey into finished hopper. Adopt flat belt conveyance, completely avoid leakage and belting, and the failure rate is lower.

3.Cement weighing system:

Cold asphalt with soil mix mixer control by computer, the powder measuring system adopts patented technology. The precision error is controllable within the range of 0.2%, the stability and accuracy are excellent.

4.Mixing System:

The mixer of cold asphalt with soil mix mixer control by computer adopts double horizontal shaft without lining board to stir. With long service life, low maintenance cost and with even and efficient stirring.

5.Control system:

Cold asphalt with soil mix mixer control by computer are all fully automatic by computer which provide fault diagnosis alarm on ready to ensure continuous production. We use famous brand for the electronic component, like SIEMENS, LS and SCHNEIDER. PLC main controller is equipped with an industrial control computer and touch screen, easy to operate. Overall management by computer control technology, Both manual and automatic at your choice, easy and reliable operation.

Detailed specifications for cold asphalt with soil mix mixer control by computer:

| Models | WBS500 | |

| Production (T/Hr) | 500 | |

| Graded kinds | 4-5 | |

| Weighing Precision | Aggregate | ±2% |

| Cement | ±1% | |

| Water | ±1% | |

| Total Power(kw) | 125 | |

| Weight (t)40 | 40 | |

| Finished Hopper Capacity (m3) | 7.5 | |

Our Service

Pre- sales service:

1. 24/7/365 to reply your inquiry.

2. To know what you needs, and suggest the correct equipment to you.

3. Provide the analysis report of the investment (cost and payback) if needed.

4. Sort out the layout drawing and quotation.

5. Make an appointment to visit our plants near you.

After-sales service:

1. To inform our clients what they should prepare before our batching plants arrive the job site.

2. Dispatch an experienced engineer to guide the installation, commissioning and training (operation & maintenance) on-site.

3. Training your operator in our factory if needs.

4. Helpline is available 24/7/365.

5. The standard spare parts are in stock, and can be sent out by DHL, TNT in 48 hours.

6. To supply the parts and training service for beyond the initial sale.

7. Our service engineer will on-line support you when you experience the problem.

8. Regular onsite visit.

Value-added service:

1. OEM service (customer-orders)

2. Relocation and overhauling the used batching plants.

3. Long-term on-site engineer service.

FAQ

Q1: What kind of equipment and service you supply?

A1: We manufacture, sell and supply after-sale service of Central mix Concrete Batching Plants, Transit mix Concrete Batching Plants and Subgrade materials continuous mixing plant.

Q2: Do you offer warranty on your equipment?

A2: Yes, we offer a full warranty on new equipment purchasing.

Q3: How long will your offer be valid?

A3: We are a manufacturer, never greedy on windfall profit. Basically, our price remains stable through a year; we only adjust our price when the international currency exchange rate changed or the labor & raw material cost changed.

Q4: How about the installation and commissioning on new purchases?

A4: We will send our technicians to your place to guide the installation, commissioning and training your operator.

Q5: how long it will take to erect the Mobile Concrete Batching Plants?

A5: Normally, it will take 7-10 days to erect the Mobile Plants, but it depend on the condition of the jobsite.

Q6: what’s the leading time for brand new Concrete Batching Plants?

A6: Within 30 days after receipt of the 30% TT down payment or 100% irrevocable L/C at sight without “soft clauses”.

Contact us

Contact: Mrs Carol

Email: carol@xdmac.com

Mobile: +86 15260469141(Whatsapp/wechat)

Previous:

Cold Aggregate Continuous Soil Cement Mixing Plant For Sale With Double Shaft MixerNext:

Road Maintenance Stabilized Soil Mixing Equipment Automatic by PLC For Sale Mobile Stabilized Soil Mixing Plant

Mobile Stabilized Soil Mixing Plant

Mobile Stabilized Soil Mixing Plant is easy to transportation, it is easy to installation.

Stationary Stabilized Soil Mixing Plant

Stationary Stabilized Soil Mixing Plant

Stabilized Soil Mixing Plant is use for foundation of the road

300t/h Stabilized Soil Mixing Plant

300t/h Stabilized Soil Mixing Plant

Our company has the production WBS300/400/500/600/700/800 type of China stabilized soil mixing plant is in my company on the basis of absorbing the international advanced mixing technology design and development of the domestic leading level commercial mixing plant, the main components international procurement, the main transmission and transportation part use domestic well-known brand product, the main parts replacement cycle is short and simple maintenance, economy.The machine is concise and easy installation, stable and reliable use, green environmental protection. Specification of Stabilized Soil Mixing Plant Main Technical Parameters of Stablized Soil Mixing Plant

500t/h Stabilized Soil Mixing Plant

500t/h Stabilized Soil Mixing Plant

Technical Advatages of Stabilized Soil Batching Plant 1.Excellent mixing performance The plant is equipment with a twin horizontal shaft mixer so that it is powerful in mixing capability ,excellent in mixing quality ,fast and high production rate . It could handle warious proportions of mixtures such as:dry hardness ,semi dry hardness,plastic and others. 2.Easy opration Use computer to contronl the whole plant either automatically or manually so that is easy to operate the plant . we use dyanmic display to show the situation of every component in operation and could store the data and print the reports. 3.Accurate weighting Computerized control system use all imported components for weighting and control aggerata,fly ash, cement and water. The sampling rate is above 120 times per second to guarantee the accuracy and the stable working performance. 4.Excellent maintenance: There are platform and ladders at every service and maintance ppsition with sufficient space to observe and operate. There are two sets of washing system:pump washing and manual washing ,and they could be in operation simultaneously . The floored design guarantees all the operations regardless of weather. Specification of Mobile Stabilized Soil Mixing Plant Main Technical Parameters of Stabilized Soil Batching Plant

600t/h Stabilized Soil Mixing Plant

600t/h Stabilized Soil Mixing Plant

Main technical features of Stabilized Soil Mixing Plant price: The universal modular design makes installation easy and reposition speedy. The double-horizontal-shaft forced mixing produces a strong mixing force and can realize rapid and even mixing. The batch feeder is equipped with press-forming steel plates which are rigid and good-looking. It uses whole sets of high-quality imported electric components made by world-famous suppliers like SCHNEIDER, SIEMENS and OMRON, which are excellent and endurable. There are automatic and manual operating modes for your choice and both are flexible and easy. Double operation of computer and control table are realized with much convenience and reliability. The double operating mode through computer and control board is easy and reliable. Abnormal working conditions and breakdowns can be automatically detected and indicated through words, sound, light and warning, which makes it easy to find and fix them. Specification of WBS600 Stabilized Soil Mixing Plant Main Technical Parameters Stabilized Soil Mixing Plant price

700t/h Stabilized Soil Mixing Plant

700t/h Stabilized Soil Mixing Plant

Stabilized Soil Mixing Plant is a combination of the removable type, stiring by twin shaft compulsory continuous form. It can be stabilized soil mixing gravel, lime stabilized soil, which is used in highways, I-level roads, II level roads, city roads ,airports ,stadiums,and other basic construction materials. This equipment is perfect performance,advanced technology, reasonable structure , reliable and easy operation, easy repair, high ratio production, accurate batching ratio, is an ideal basic construction materials mixing equipment for construction sites. Specification of Stabilized Soil Mixing Plant Main Technical Parameters Stabilized Soil mixing machine

800t/h Stabilized Soil Mixing Plant

800t/h Stabilized Soil Mixing Plant

Stablized Soil Mixing Equipment 1.utilized modular assembled 2. integration structure and many kinds combining form 3.It is easy to layout, dismantle, load and transport 4.Total machine use industrial computer to control,operate easily,work reliably,To any high way,airport and etc.base contruction. Environment protection 1. To save energy and recycle waste. provides new facilities in consideration of environment protection, 2. Enclosed aggregate delivery system reduces noise greatly. 3. Pulse type dust colleector with bag cartridge solves teh problen of powder emission; 4. Concrete recycling equipment ,an integrated system in reclaiming aggregate and water treatment, reduces en-vironment pollution to the lowest level Main Technical Parameters Stablized Soil Mixing Equipment

300t/h Mobile Stabilized Soil Mixing Plant

300t/h Mobile Stabilized Soil Mixing Plant

Main features of MOBILE CONTINOUS SUBBASE SOIL MIXING PLANT 1. YWBS series MOBILE STABLIZED SOIL MIXING PLANT is required for grass-roots material construction ,such as road,city way,airport,playground and etc. 2.we utilized advanced technology to study prouducing at home and abroad,which is special for mixing plant. 3.Raw material can use lime,soil,sand,fly ash,cement and etc. raw material,and for producing cement stabilization grit,ashes stabilization base material,,meanwhile,it can press concrete and etc.base material. 4.There is two kinds that is moveable and modular ones up to construction requirement. Specification of Mobile Stabilized Soil Mixing Plant Layout Drawing of Mobile Stabilized Soil Mixing Plant Main Technical Parameters of Mobile Stabilized Soil Mixing Plant

Friendly Links :

Copyright © 2015-2026 Fujian Xinda Machinery Co., Ltd..All Rights Reserved.Powered by dyyseo.com